-

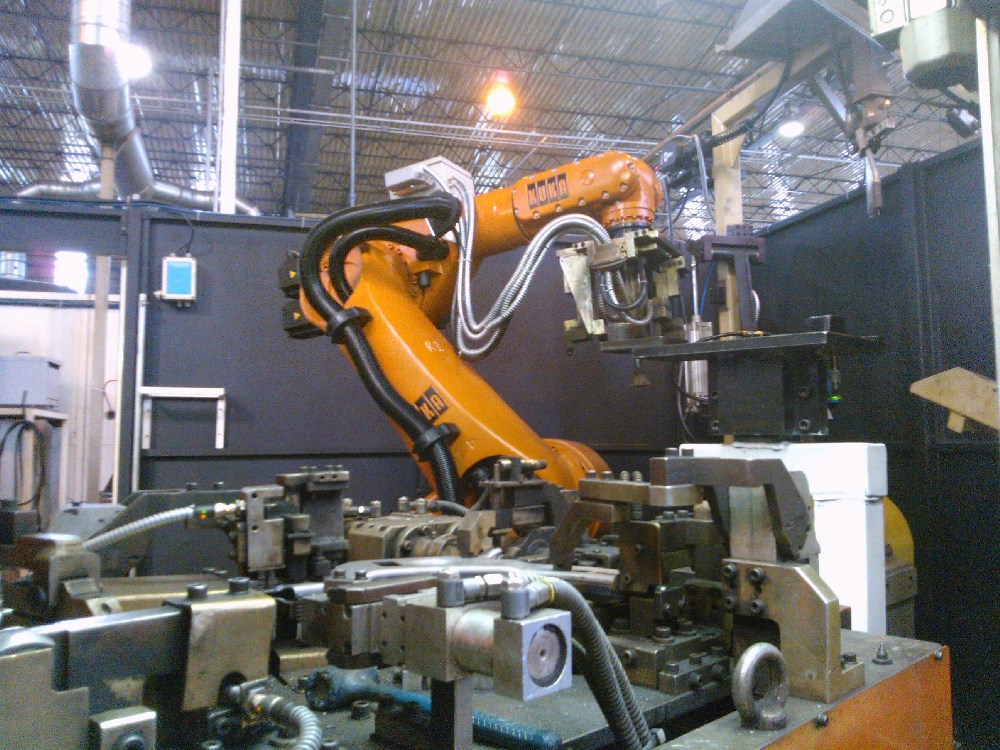

Robotic Welding MachinneTALK WITH USLEARN MORE

Robotic Welding MachinneTALK WITH USLEARN MORE -

Network devices and SwitchsREQUEST A QUOTELEARN MORE

Network devices and SwitchsREQUEST A QUOTELEARN MORE -

Gateways profinet modbusREQUEST A QUOTECONTACT

Gateways profinet modbusREQUEST A QUOTECONTACT -

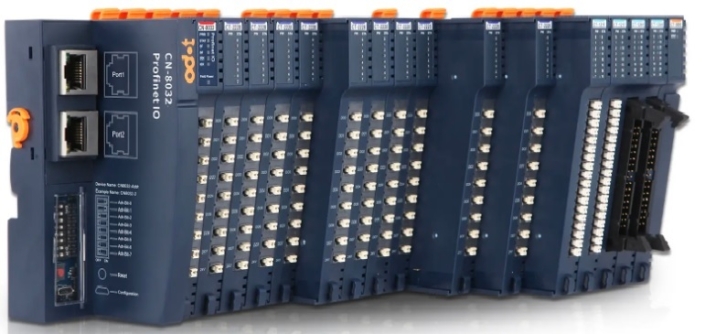

Remote I/O CAN Profinet Ethenet I/PREQUEST A STUDYCONTACT

Remote I/O CAN Profinet Ethenet I/PREQUEST A STUDYCONTACT -

Remote I/O CAN Profinet Ethenet I/PREQUEST A STUDYCONTACT

Remote I/O CAN Profinet Ethenet I/PREQUEST A STUDYCONTACT

Importador MEGMEET para máquinas solda Robotizada e Manuak Sinérgica, Pulsada, TIG e solda Laser que substitui com ótimo custo beneficío de velociada a solda TIG para soldagem de Inox, Aço e Alumínio e Titânio. Referência em tecnologia de soldagem ponta, contamos tamém com sistemas de I/O distribuído ( Remota I/O) para os mais diversos protocolos de rede, auxiliando a coleta de dados e IoT, Gateways e conversores de protocolo.

We have solutions to meet the most common industrial network protocols, such as profinet, ethernet I/P and Ethercat, with much shorter delivery times than the traditional ones.

Discover our product line.

![]() Robotic welding machinne with 24 months of warranty to steel inox and alloy weld.

Robotic welding machinne with 24 months of warranty to steel inox and alloy weld.

![]() Sinergic, pulsed , single pulse and double pulse technology, to 300A unti 500 A weld current

Sinergic, pulsed , single pulse and double pulse technology, to 300A unti 500 A weld current

![]() Equipments with network communication like, Ethernet I/P, Devicenet, Modbus, WIFI, ETHERNET

Equipments with network communication like, Ethernet I/P, Devicenet, Modbus, WIFI, ETHERNET

![]() Full digital intelligent control, ultra-high 100KHz inverter frequency, “zero delay” sampling circuit [1], making the power response accurate for each drop transition state

Full digital intelligent control, ultra-high 100KHz inverter frequency, “zero delay” sampling circuit [1], making the power response accurate for each drop transition state

![]() Unique power supply power discharge design, current drop slope is as high as 10,000 amps/millisecond, realizing “zero impact” of current force on molten pool at the time of droplet transition[2]

Unique power supply power discharge design, current drop slope is as high as 10,000 amps/millisecond, realizing “zero impact” of current force on molten pool at the time of droplet transition[2]

![]() Novo modo JOB, livre para combinar todos processos de soldagem

Novo modo JOB, livre para combinar todos processos de soldagem

pulsed / sinergic / double pulse / CC double / CC+ double pulse / You decide!

Main Benefits

- Local Technical support to integrate with all brands of robot.

- Extended Warranty

- Spare parts

Learn More

Main caracteristics of PM400 series

The PM 400N source is mainly used for structural steel welding in heavy engineering, steel structure production, container and reservoir production, transportation engineering, etc. with pulsed synergic technology. Perfectly copes with work in conditions severity of modern production. Withstand – 100% load, high dust, vibration, significant drops in power supply. Wire feed speed stability is ensured through the use of optical sensors and high speed feedback between the source and wire feed mechanism. With the help of the arc length control function, uniformity of weld formation and depth of penetration are achieved.

The function of starting current and filling a crater allows you to avoid defects at the beginning and end of welding. Automatic (synergy) or manual adjustment of welding modes. The liquid-cooled unit is activated by a button on the power supply panel, which allows quick switching between gas-cooled or liquid-cooled torches.

Technical data PM400

| Voltage | 380V ( 325V a 418V) |

|---|---|

| Refrigeration | Colled air |

| wire diammeter | 0,8mm to 1,2mm |

| Welding Current | 30 A a 300 A 100% duty |

| Welding Process | MIG /MAG / MMA/ Single / Double Pulse |

| Base Material | Steel, Alloy Inox |

| Gas | 100% CO2, 80%AR 20%, 75%AR 25%CO2 100% AR |

| Weight | 52kg |

| Dimensions | 300X 480 X 260 mm |

| Power | 24KVa |

| Operation temperature | -39° C a +55°C |

Main specs CM400-R

CM 400R source is mainly used for structural steel welding, steel structure production, container and reservoir production, transportation engineering, etc. severity of modern production. Withstands – 100% load, high dust, vibration, significant drops in power supply. Wire feed speed stability is ensured through the use of optical sensors and high speed feedback between the source and wire feed mechanism. With the help of the arc length control function, uniformity of weld formation and depth of penetration are achieved.

The function of starting current and filling a crater allows you to avoid defects at the beginning and end of welding. Automatic (synergy) or manual adjustment of welding modes. The liquid-cooled unit is activated by a button on the power supply panel, which allows quick switching between gas-cooled or liquid-cooled torches.

CM400 Technical Data

| Voltage | 380V ( 325V a 418V) |

|---|---|

| Refrigeration | Colled air |

| wire diammeter | 0,8mm to 1,2mm |

| Welding Current | 30 A a 300 A 100% duty |

| Welding Process | MIG /MAG /MMA |

| Base Material | Steel |

| Weight | 52kg |

| Dimensions | 300X 480 X 260 mm |

| Power | 24KVa |

| Operation temperature | -39° C a +55°C |

Main technical data DEX3000 series

The DEX 3000 power source is mainly used for manual and robotic welding of steel / aluminum / stainless steel / coated electrode / solid wire / metal cored / flux cored wire in wire gauges 0.8mm to 1.2mm, 210A for the production of metal structures where the need for cost benefit / quality impacts on the project, it has synergic / pulsed technology, and JOB control as well as penetration control with welding speeds of

It copes perfectly with working conditions severity of modern production. Withstands – 100% load, high dust, vibration, significant drops in power supply. Wire feed speed stability is ensured through the use of optical sensors and high speed feedback between the source and wire feed mechanism. With the help of the arc length control function, uniformity of weld formation and depth of penetration are achieved.

DEX DM/PM 3000 Series Technical Data

| Voltage | 380V ( 325V a 418V) |

|---|---|

| Refrigeration | Forced Air / Watter colled |

| wire diammeter | 0,8mm to 1,2mm |

| Welding Current | 30 A a 207 A 100% duty |

| Welding Process | Mig / Mag / Co2 /MMA /Double pulse /pulsed *Only DEX PM |

| Base Material | Steel / Aluminiun / Alloy * only DEX PM |

| Weight | 25Kg |

| Dimensions | 300X 480 X 260 mm |

| Power | 9,5 Kva |

| Operation temperature | -39° C a +55°C |

| Communication | Devicenet / Ethernet I/`P /Analog /Can Open |

Comunication / Network

Distribuidor ODOT líder no desenvolvimento de equipamentos para comunicação e coleta de dados, gateways rede, conversores de protocolo, switch, conversor de protocolo MPI Ethernet, com variados protocolos de redes, I/O remotos

CAN PROFINET, ETHERNET I/P, PROFIBUS, MODBUS RTU, MODBUS TCP Protocols

Main Benefits

- Locally Technical support

- 24 months Extended warranty

- Spare parts

- with CE,UL ,ISO9001:2015

- Data acquisition automation leader and solution provider

- Quality and confiability

- Reduction of up to 30% in installation and start-up labor costs

Fast Ethernet Industrial switchs for panel mouting

10/100 /1000 Mbps auto negociação,(Auto-MDI/MDI-X)

5/8/10/16 ports un-manageable

Suporta IEEE 802.3 for 10BaseT

IEEE 802.3u for 100BaseT and 100BaseFX

Aluminum Shell

Power supply 9- 36V

Din rail montaded

3 years of garanty

Gateways

Conversores de protocolo

Modbus RTU para Modbus Ethernet TCP /IP

Modbus RTU/ASCII para Profinet

Modbus RTU para Profibus

CAN Open para Modbus Ethernet TCP /IP

4 Portas Serial Modbus RTU para Modbus Ethernet TCP /IP

PPI/MPI/PROFIBUS para Ethernet TCP /IP

TTY > Modbus para Ethernet TCP /IP

Power 9-30V

ODOT-S7MPIV2.0: Interface PPI/MPI/PROFIBUS para EtherNet

♦ Installed on the PPI/MPI/PROFIBUS communication port of the PLC, usually without external power

Siemens S7, incluindo MicroWIN,STEP7, TIA Portal, WinCC etc

Integrated with Modbus-TCP server, Modbus data area can be automatically or edited to map to register S7-200/300/400

♦ S7TCP connection and Modbus-TCP communication can be performed simultaneously

Remote I /O for Industrial networks

Flexible protocol module and plug and play I/O module, features as below:

1. Designed with a maximum of 32 modules, each I/O module is built with 16 channels and each has an LED indicator.

2. Supports a total of 512 I/O points and autocorrect;

3. The I/O module's backplate cable can be extended up to 15 meters for use in multiple panels;

4. Working temperature of -40~85℃ with a 3-year guarantee;

5. High-speed 12M backplate bus, with 32 digital quantity modules with a 2ms update period and 2ms analog quantity;

6. Supports Modbus-RTU, Modbus-TCP, Profinet, Profibus - DP (DPV0), EtherCAT, Ethernet/IP and other up to 12 main flow protocol types.

Caracteristicas Principais BOXIO

Módulo de E/S integrado e totalmente configurável permite mesclar entradas /saidas /encoder /analógico 4-20ma /PT100 /PT1000 analógico 0-10VDC

O módulo de E/S integrado da série ODOT B consiste em um case, um módulo de comunicação (placa rede) e módulos de E/S estendido conforme a necessidade. A placa COMM correspondente a interface de comunicação (rede). Os principais protocolos de comunicação industrial incluem Modbus, Profibus-DP, Profinet, EtherCAT, EtherNet/IP, CANopen, CC-Link, PowerLink, etc. O módulo de E/S estendida é dividido em seis categorias: módulo de entrada digital, módulo de saída digital, módulo de entrada analógica, módulo de saída analógica, módulo especial e módulo de E/S híbrido, podendo ser configurado de acordo com a necessidade do cliente, por exemplo somente entradas somente saídas, 3x conjuntos entrada 1x módulo saída etc.

The COMM board and extended IO modules can be freely combined based on site requirements. The integrated IO module can reduce the cost when there are few data points.

Conversor de Protocolo MPI / PPI /Profibus para Modbus TCP Ethernet Rj45

– Instalado na porta de comunicação PPI/MPI/PROFIBUS do CLP, geralmente sem fonte de alimentação externa, esse é o gateway mais fácil de configurar do mercado para comunicação com Siemens, esqueça os conversores Usb que vivem caindo a comunicação.

– Suporta drivers de comunicação Ethernet Siemens S7, incluindo MicroWIN, STEP7, TIA Portal, WinCC, Indusoft, Keepserver EX.

– Integrado ao servidor Modbus-TCP, a área de dados Modbus pode ser automaticamente ou editada para mapear para registrar S7-200/300/400

– A conexão S7TCP e a comunicação Modbus-TCP podem ser realizadas simultaneamente.

– Permite programação do PLC através da conexão ethernet sem necessidade de conversor USB, permite ainda a interligação com switch para programação remota PLC, simultâneamente com uma conexão modbus de um sistema supervisório, com leitura direta de DB´s via modbus tcp.

* Configuração inicial deverá ser realizado pelo NETLINK,(download configurador módulo)

Ethernet Interface

Protocol: S7 Ethernet, Modbus-TCP

TCP Connections: Max. 32

Ethernet Port Quantity: 1

Rate: 10/100Mbps, Self-Adaption MDI/MDIX

Interface: 8PinRj45

Welding peripherals

Peripheral welding equipment to improve your productivity with pneumatic torch cleaning stations, with wire cutting and anti-spatter application

Main Benefits

- Locally Technical support

- 24 months Extended warranty

- Spare parts

- with CE,UL ,ISO9001:2015

- Welding automation leader

- Quality and confiability

Pneumatic torch clean units

The fitting allows for nozzles with a maximum outside diameter of 32 mm;

● No need change of main blocks

● Pneumatic motos with high torque

● Overload protection and long service life;

● Special filters can filter out oil and impurities in the gas path;

● Oil injection in a closed space;

● Used oil could be collected

● TCP check point

● Automatic clean, no manual operation required

ABOUT US

FEB positions itself in the market as a systems integrator, a partner company for the development of customized solutions for new technologies in the field of robotic automation and special machines.

Security and Privacy

History

Service

Opening hours

Nosso suporte funciona diariamente das 08:00 as 22:00h através do Tel+55(11)-99402-6561

- Monday To Thursday 08:00am as 6:00pm

- Friday 08:00am as 6:00pm

- Saturday / Sunday Closed