Developed to recycle employees, they can be delivered in the format "IN CONPANY" with a robot provided by us or at FEB facilities.

It has great support material in addition to robots dedicated to the practical part.

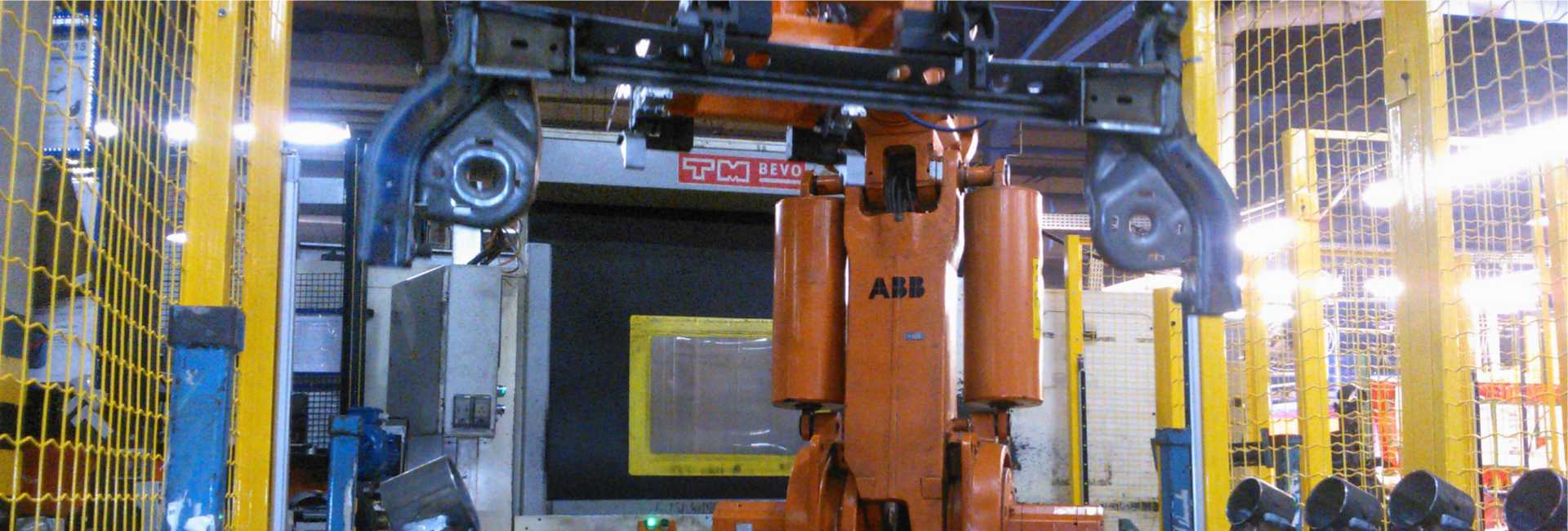

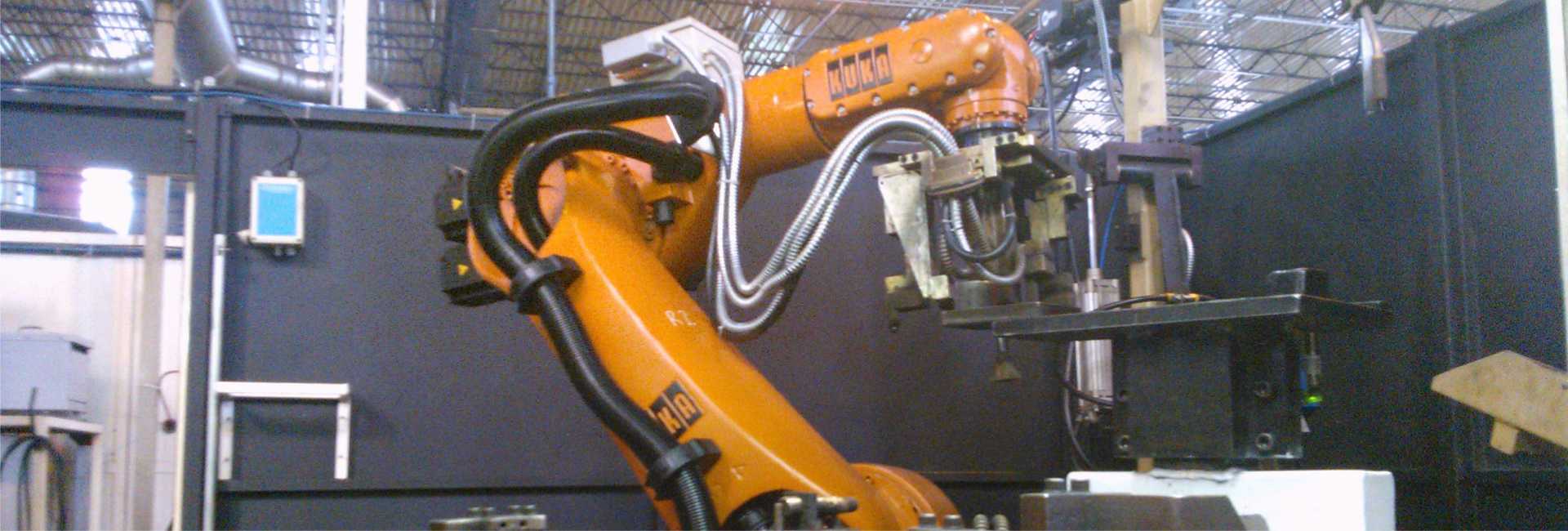

The FEB supply services of corrective maintenance and maintenance contracts. Our technicians are trained directly at the manufacturers, with specialization courses abroad.

We also provide technical assistance services on CNC FANUC, SIEMENS and PLC. Solid knowledge of Profibus and Devicenet industrial networks. Workforce of KUKA, FANUC, MOTOMAN, ABB and KAWASAKI robots

The FEB supply predicitve services, and maintenance contracts. Our technicians are trained directly at the manufacturers, with specialization courses abroad.

We carry out preventive maintenance in accordance with the manufacturer's maintenance manual, following all the specifications and recommended materials, always in accordance with the equipment's hour meter. As a differential in all our preventive maintenance, we carry out an analysis of metallic particulates in the lubricants removed for an early diagnosis of bearing wear in the gearboxes, thus avoiding unexpected downtime.

We operate in the segment of mechanical design of machines and devices with state-of-the-art CAD software, projects in CATIA, SOLIDWORKS or SIEMENS NX and EPLAN electrical projects in the area of special devices and machines, low and medium voltage electrical projects.

FEB also offers a differential solution not only in the supply of equipment but also in the supply of specialized labor for Certification Consulting for old machines at NR12.

We operate in the segment of providing CNC machining center services for small batches of parts with machining of 2D and 3D parts in addition to electrical and mechanical assembly, be sure to consult us.

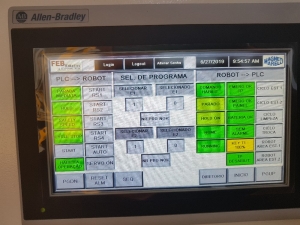

Programming services in PLC / HMI /Inverters, Siemens, Rockwell, Allen Bradley, Fanuc Yaskawa SEW in all versions of TIA Portal, Step7, Step5, RSLOGIX, Studio5000 software, and in the most varied industrial networks such as Devicenet, Profibus, PROFINET , PROFISAFE, Modbus TCP, Ethernet I/P. Professionals with extensive experience within the industry.

Development of supervisory systems has become a necessity nowadays, this need ranges from the production control to indicate idle times, maintenance stops, etc., through the traceability control for security items with database and finally arriving at industry 4.0, integrating the entire shop floor with our customers' ERP management system.

Our systems are developed with the most current tools, we use the INDUSOFT / SCADA system, which can be optimized for the most varied needs and daily tasks.